Treated Wood

The 5 Most Important Facts When Using Chemically Treated Wood On Projects

As a company that knows how important it is to respect the environment and to have good forestry management through a proper procedure of the resources, we highly recommend choosing natural lumber instead of chemically treated wood.

Although the wood treatment process is carried out under the authorities’ strict control to avoid contamination, this was not the reality in the past. In this article, we will tell you how everything started and how the effects of the chemical modification of wood have been minimized. We will also emphasize why there is no need to prefer chemically treated wood when there are natural, top-quality alternatives.

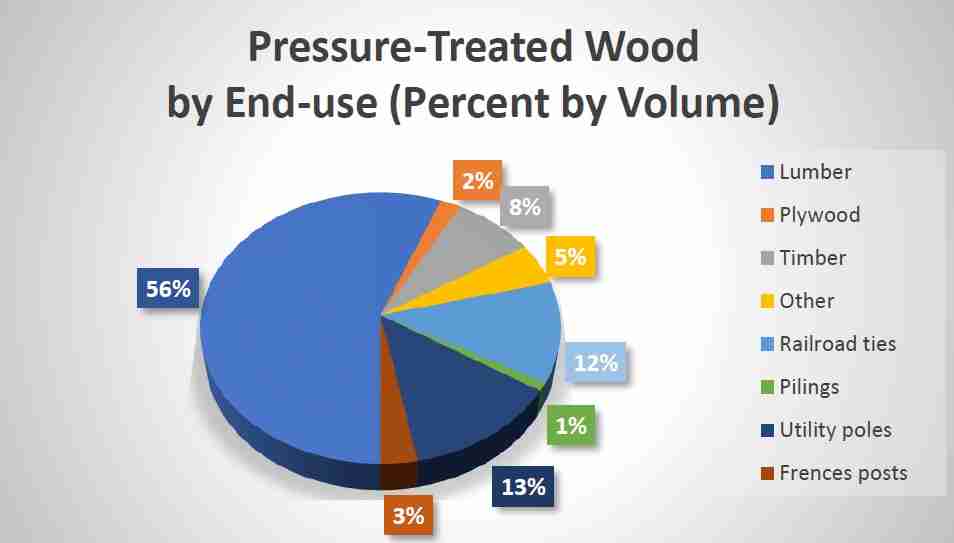

According to some environmental investigations published on different scientific websites, Americans use approximately 3.8 billion board feet of preservative-treated lumber per year in the building industry in North America. Treated wood accounts for over 21% of all dollars spent on timber products, according to the American Wood Preservers Institute—AWPI.

Wood preservative products control wood degradation problems due to fungi, rot or decay, molds, or insect damage. The treatment process and the use of treated wood, for instance, can harm human health and the environment. Luckily, at the moment, both scenarios have been controlled.

For people from the US, it is very common to choose wood for outdoor construction. This material is the preferred option due to its characteristics of durability, hardness, and resistance to external factors. The thing is that only some of them are like this naturally. Others need to be chemically treated in order to achieve these properties.

What Are The Most Common Preservatives Used In Chemically Treated Wood?

The Environmental Protection Agency, known as EPA, protects people and the environment from significant health risks related to pollution problems. It also develops and enforces environmental regulations.

According to this organization, the most commonly used preservatives in treated wood are chromated arsenicals, creosote, and pentachlorophenol. These elements currently undergo a registration review by the EPA to ensure that the products can perform their intended function without creating unreasonable risks to human health and the environment. This process occurs every 15 years.

In the 1930s, researchers succeeded in “fixing” arsenic salts in wood using sodium dichromate. Copper sulfate, an effective fungicide, was added to the formulation to create today’s most common wood preservative: chromated copper arsenate.

In 2008, EPA determined that chromated arsenicals, creosote, and pentachlorophenol could remain in use as long as certain mitigation measures identified in the Reregistration Eligibility Decision Documents (REDs) were implemented. These measures included engineering controls such as ventilation and automatic doors for locking and unlocking treatment cylinders.

Wood preservatives were used in North America around 1730 when wood was dipped in a solution of arsenic salts to protect against insect attack. Wood soaked in a solution of copper sulfate was also found to be resistant to decay. Because of the solubility of these metals in water, the treatments only worked if the wood stayed dry. Creosote, patented in 1831, was the first wood preservative effective in ground-contact and high-moisture areas.

In 2019, EPA completed its draft risk assessments for chromated arsenicals, creosote, and pentachlorophenol as a part of its registration review. In each case, EPA found that although the measures required by the Reds reduced worker exposure, these products continued to pose health risks of concern to those who applied them. Creosote and chromated arsenicals were also found to pose risks to the environment.

In 2021, EPA issued proposed interim decisions for chromated arsenicals, creosote, and pentachlorophenol to address the human health and environmental risks of using these chemicals. EPA determined that pentachlorophenol’s risks outweighed its benefits and proposed cancelation. For creosote and chromated arsenicals, EPA proposed additional mitigation measures to protect workers’ health in wood treatment facilities.

Other Preservatives Used With Treated Wood

Before discussing other preservatives used on chemically treated wood, let’s see how they act on wood. At least most of them follow this procedure. The key to an excellent pressure treatment process is to let the preservative penetrate deeply into the wood.

The lumber is loaded into a cylindrical pressure chamber, and high pressure forces the preservative into the wood cells. For maximum penetration and retention of preservatives, the pressure chamber is sometimes first depressurized to pull air out of the wood cells.

Listed below are other preservatives that most treated wood has in its composition and effect.

Chromated Arsenicals

Wood preservatives containing chromated arsenicals include some that have chromium, copper, and arsenic in their composition. Since the 1940s, wood has been pressure treated with chromated arsenicals to protect the wood from rotting due to insect and wood-boring marine attacks. From the 1970s to the early 2000s, most of the wood used in outdoor residential settings was chromated arsenical-treated wood.

In 2003, the use of this preservative was canceled by EPA in most residential settings, including decks and children’s play sets. Now, it can be used only by certified pesticide applicators. It can be used to produce commercial wood poles, posts, shakes, shingles, permanent foundation support beams, pilings, and other wood products permitted by approved labeling.

Creosote

This preservative is obtained from the high-temperature distillation of coal tar. Pesticide products containing creosote as the active ingredient are used to protect wood against termites, fungi, mites, and other pests.

It can be used in outdoor settings such as railroad ties and utility poles. Indoor applications of creosote are prohibited, as well as application to wood intended for use in interiors or use in contact with food, feed, or drinking water.

Pentachlorophenol

Pentachlorophenol, also known as PCP, was one of the most widely used biocides in the United States before 1987. At that time, its uses as a herbicide, defoliant, mossicide, and disinfectant were removed from product labels.

Nowadays, PCP is a restricted-use pesticide applied only for commercial purposes, primarily for treating utility poles. Only pressure and heat treatments of PCP are allowed.

Propiconazole

EPA has approved this preservative for preserving wood used in millwork, shingles and shakes, siding, plywood, structural lumber, and timbers and composites used in above-ground applications only. It has been used since 1981.

Triadimefon

The Triadimefon is a triazole fungicide that was first registered as a wood preservative in 2009. EPA approved it for preserving wood-based composite products and wood products intended for above-ground. You can use it on wood decking, patio furniture, millwork, guardrails, utility poles, foundation pilings, and fences.

Some new wood preservatives have been recently approved for residential uses by the EPA. These wood preservatives have lower toxicity profiles when compared to older wood preservatives.

- Alkaline Copper Quaternary (ACQ): This water-based wood preservative prevents decay from fungi and insects. It also has relatively low risks, based on its components of copper oxide and quaternary ammonium compounds.

- Borates: It is also a water-based wood preservative registered by EPA and government agencies throughout Asia, North America, and Europe.

- Copper Azole: It is a fungicide and water-based insecticide wood preservative that prevents fungal decay and insect attack.

- Copper Naphthenate: It is effective in protecting wood against insect damage. This preservative is used to brush, dip, spray, and pressure-treat lumber in the ground, water, and above-ground contact.

Considerations When Choosing Chemically Treated Wood

Although the process of treating wood has become less harmful to the environment and human health and is now controlled by environmental companies, there is no better choice than natural species.

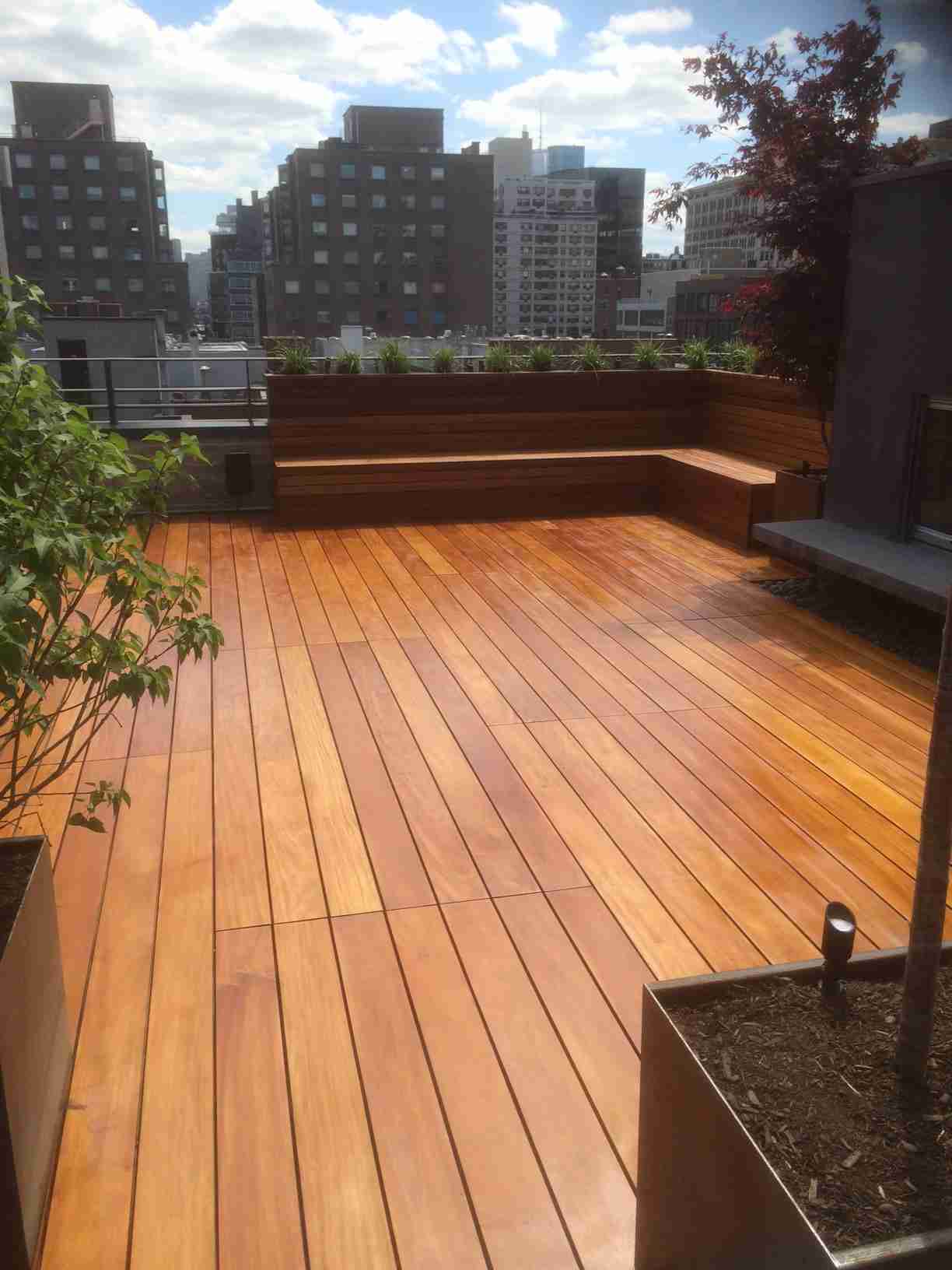

Our premium tropical hardwoods such as Ipe, Cumaru, Garapa, Jatoba, and Tigerwood are naturally resistant to all those treats for which other types of wood are modified. They all have special oils in their composition that make them impenetrable to rot, mildew, water, insect damage, and, most of them, even fire and salt water.

These five hardwoods are the stars of our elite line called Platinum Woods. This superior quality collection offers an extra grading level, which architects and designers prefer for luxury homes and exquisite exteriors. Check them on our digital brochure.

But for those who prefer treated wood, here are some important considerations.

1. Leaching of CCA into the ground or water

According to some scientific articles, this has always been one of the most important considerations with wood preservatives: whether the chemicals will leach out of the wood into the ground, groundwater, or open water.

Bruce Johnson, a wood preservation expert at the Forest Products Laboratory in Madison, explained that when you have a well-treated piece of wood handled in the recommended manner during and following treatment—whether it’s in a marine or aquatic environment or the soil—the amount of leaching that occurs has minimal impact on the serviceability of the wood. This means that some leaching occurs, but it can be minimal.

2. Chemical spills and leaks

While many people are concerned about what goes into the wood in a chemical treatment process and the leaching of CCA, using some raw chemicals earlier in the process is more important.

Chemical manufacturing plants, blending facilities, and wood treaters are all regulated by the EPA in the United States, and the Department of Transportation controls the mobility of hazardous substances. Although no significant spills or roadway accidents have been reported to date, the danger exists as long as dangerous substances are used.

- Disposal of treated wood

There is currently no environmental way to dispose of treated wood once its usefulness is over. In landfills, it takes up significant space and won’t break down for many decades. While the heavy metals will presumably remain locked up in the wood for this time, the wood might release the chemicals into the landfill environment.

Disposal in municipal incinerators releases some arsenic, chromium, and copper into the air. Most are captured with pollution control equipment. Even though these heavy metals are successfully kept out of the air, they end up in incinerator ash, which is highly leachable. It is established in some scientific papers that, in the future, there will be a prohibition on the incineration of CCA-treated wood in municipal solid waste incinerators.

- Health risks to building occupants

Can chemicals get into the indoor environment or onto occupants’ skin, where they could be ingested or absorbed? That is the biggest concern to people with structures made of treated wood.

In a study of airborne arsenicals in basements of houses with all-weather wood foundations (constructed of CCA-treated wood), virtually nothing was found, according to Bruce Johnson of the Forest Products Laboratory.

The ability to get CCA on your skin by walking on or touching treated wood may be reduced by surface coatings on the wood or the use of premium treated wood that has a moisture-repellant mixed with the preservative.

- There are some benefits of using treated wood

It is essential to highlight that there are some environmental benefits as well when choosing treated wood. One apparent environmental benefit of preservative-treated wood is a saving in energy and resources resulting from increased longevity of the wood.

The American Wood Preservers Institute (AWPI) claims that without treated wood, “our requirements for railway, utility, construction and marine industries would have exhausted our resources many years ago.”

To summarize, there is no better alternative than natural products, and that’s a fact no matter what industry we’re talking about. In this case, our tropical hardwoods are naturally resistant to rot, insect damage, mildew, water, and weathering. They are chemical-free, so there is no risk of releasing toxic gases into the environment.

On the other hand, with chemically treated wood, the use of preservatives is imminent, and there is a risk of contamination to the environment and humans. The good thing is that, at the moment, the wood treatment process is controlled by environmental companies that are also doing some studies about the preservatives to manage their effects as much as possible.